Browse our Catalog

Metal Hose, Stripwound

.jpg)

What type of stripwound metal hose do I need, you ask? Well, you've come to the right place!

We'll help guide you through the answers right here, including the advantages and disadvantages of stripwound metal hose. And after reading, if you are clear on which hose you need, you can order below from the variety that we carry from Hose Master; or if you still are unsure and have further questions, please contact us at (800) 633-2948 or sales@ehlynn.com and one of our equipment specialists would love to provide you with more information and assist you in ordering the proper hose.

On to the answer...

In a nutshell, stripwound metal hose is a rugged product made from a strip of steel that is profiled and continuously wound around a mandrel to form a hose. It is typically used as a guard, exhaust hose and for the transfer of dry bulk materials. In particular, Hose Master’s proprietary manufacturing process yields an extremely consistent and balanced profile that maximizes strength and flexibility.

Now, there are a few different types of stripwound metal hose, and choosing the best one to fit your needs all depends on your particular application for which the hose will be used for.

Roughbore Interlocked

The strip is formed with legs that interlock to form a hose that is flexible and ideally suited for conveying dry bulk materials, gas exhaust, or used as a protective cover. This would be the Interflex Metal Hose, unpacked that we carry.

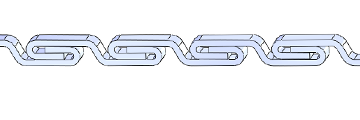

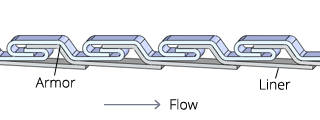

Smoothbore Interlocked

Designed to reduce damage to delicate materials, another steel strip is added inside a roughbore hose to provide a smooth interior surface. Smoothbore hose is also flexible and used for dry bulk conveying. This would be the Ultraflex Metal Hose, unpacked that we carry.

Packed Interlocked*

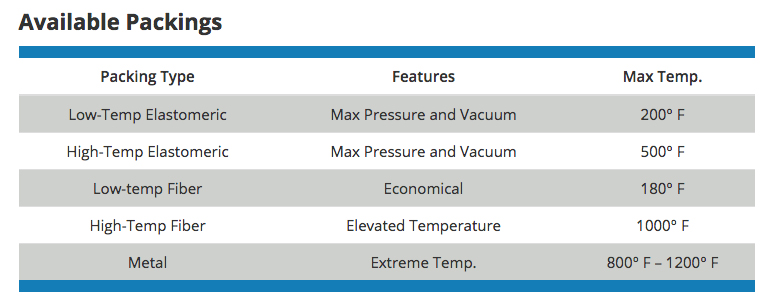

Packing may be added to interlocked hose to minimize leakage through the hose profile. The most effective packings are made from resilient materials such as elastomers and, to a lesser extent, cotton.

Harder materials (stainless steel and copper) are also available if requested.

This would be the Interflex and Ultraflex Metal Hose that we carry.

.png)

.png)

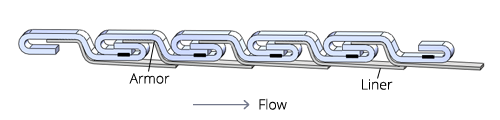

Torque-Resistant Interlocked

Designed for torque resistance and enhanced sealability, this product resists twisting, unwinding, and strip flare-up after cutting.

Torque-resistant hose is manufactured in either roughbore or smoothbore constructions. This would be the T-Rex (roughbore) and T-Rex SB (smoothbore) that we carry.

.png)

*When to Consider Packing:

Interlocked metal hose, by the nature of its construction, is not pressure tight. However, pressure and media infiltration through the interlocked wall can be minimized by the insertion of one of a variety of packings into the wall during hose manufacturing. Packing consists of a continuous cord or strand of elastomer, or other material which is locked into a special channel between the interlocked hose wall layers. The choice of packing material is tailored to the demands of the specific application.

- Faster loading and unloading – less friction between media and hose material.

- All-metal construction is self-grounding – No need to worry about grounding wires, static buildup or combustible dust.

- Resistance to the elements – Stainless steel holds up extremely well to temperature fluctuation, sun exposure

and puncture. Kink free – Stripwound’s construction prohibits it from kinking and resists overbending.- Hoop strength – Stripwound’s superior hoop strength makes it resilient to crushing.

- Not pressure-tight construction – Very fine media (powders or dust) can permeate in or out of the hose over time.

- Liquids – Water and moisture can penetrate the hose if saturated.

- Highly abrasive media – While good for most dry materials, media that is extremely abrasive at high velocities will wear through the hose.

- Not approved for sanitary service –

Stripwound hose is suitable for raw foodstuffs (grain, peanuts, corn, seeds, etc.) but not finished or semi-finished foods

Finally, the following design parameters must be determined in order to properly design a metal hose assembly for a particular application. The acronym “S.T.A.M.P.E.D.” is used by Hose Master to help remember them all:

- Size – The diameter of the connections in which the assembly will be installed is needed to provide a proper fit. This information is required.

- Temperature – As the temperature to which the assembly is exposed (internally and externally) increases, the strength of the assembly’s components decreases. If you do not provide this information it will be assumed that the temperatures are 70 degrees F.

- Application – This refers to the configuration in which the assembly is installed. This includes the dimensions into which the assembly must fit as well as the details of any movement that the assembly will experience. This is required since you cannot determine the proper length or proper hose type without it.

- Media – Identify all chemicals to which the assembly will be exposed, both internally and externally. This is important since you must be sure that the assembly’s components are chemically compatible with the media. If no media is given, it will be assumed that both the media and environment are compatible with all of the available materials for each component.

- Pressure – Identify the internal pressure to which the assembly will be exposed. Stripwound metal hose, by the nature of its construction, is not pressure tight. However, pressure and media infiltration through the stripwound wall can be minimized by the insertion of one of a variety of packings into the wall during hose manufacturing. If no pressure is given it will be assumed that there is no pressure.

- End Fittings – Identify the necessary fittings. This is required since fittings for the assembly must be chosen to properly fit the mating connections.

- Dynamics – Identify the velocity at which the media will flow through the assembly. Extremely high flow or abrasive media can cause premature failure. If no velocity is given, it will be assumed that the velocity is not fast enough to affect the assembly’s performance.